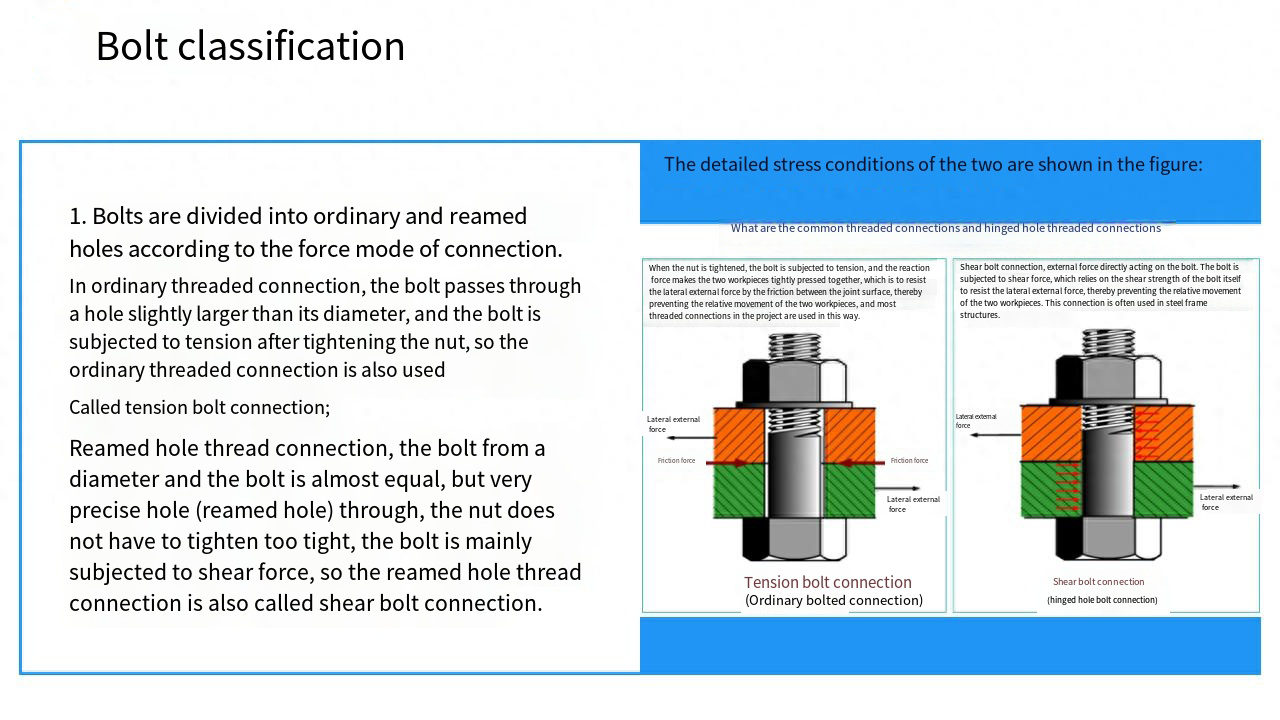

Akunakuthiwa intambo eqhelekileyo kunye ne-reamed intambo yomngxuma, kodwa ibholithi eqhelekileyo kunye nebholithi yomngxuma reamed, kuba inxalenye yentambo yezi zimbini iyafana, umahluko kukuba inxalenye yentonga ngaphandle kwentambo.Ngenxa yokuba inxalenye yentambo iyafana, i-axial force iyafana.Kukho umsantsa phakathi kwenxalenye yentonga ecacileyo yebholiti eqhelekileyo kunye nomngxuma, kwaye amandla aguquguqukayo yindawo yokukhuhlana kuphela kumphezulu woqhagamshelwano xa ibholithi iqinisiwe (ngokuqinisekileyo, ukuba ucinga ngenene ukusika, amandla anqamlezayo. ngokwenene ngamandla okucheba ebholithi).Ukulingana kwebholiti yomngxuma ehlaziyiweyo kunye nomngxuma kukunyamezela, kwaye amandla anqamlezayo ngamandla okucheba kwebholiti yomngxuma ephinda-phindayo.

Jonga ngaphandle

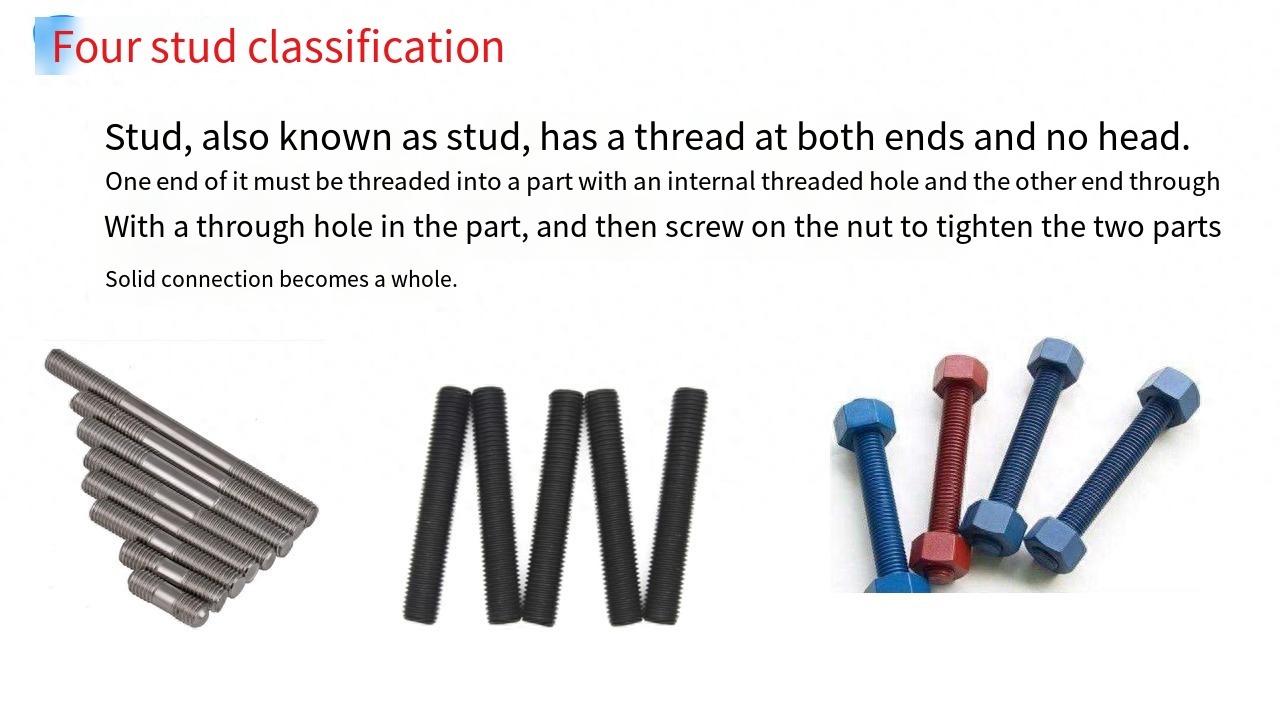

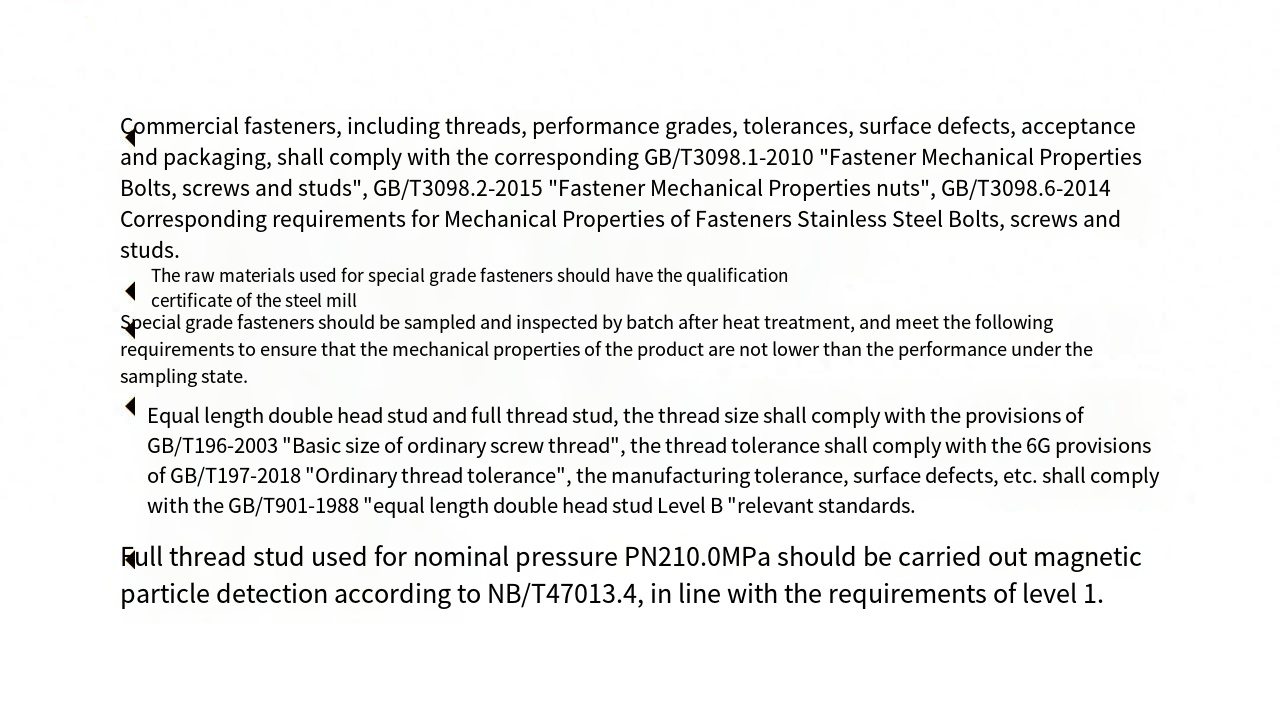

bm = 1d i-double stud isetyenziselwa ukudibanisa phakathi kweentsimbi ezimbini ezidityanisiweyo;I-GB/T897-1988 “i-Double-ended stud bm=1d” (i-bm ibhekisa ekupheleni komngxunya we-screw obizwa ngokuba yi-screw end, ubude be-bm bunxibelelene nezinto zenxalenye eza kugqunywa: bm=1d yentsimbi. kunye nobhedu, apho u-d ebhekisa kwidayamitha engaphandle yomsonto, ibhekisa kwidayamitha enkulu.)

bm=1.25d kunye ne-bm=1.5d i-double stud ngokuqhelekileyo isetyenziselwa ukudibanisa phakathi kwekhonkco yentsimbi kunye nentsimbi yentsimbi;GB898-1988 "Double stud bm = 1.25d", GB899-1988 "Double stud bm = 1.5d".

bm = 2d i-stud ephindwe kabini isetyenziselwa ukudibanisa phakathi kwe-aluminium alloy connector kunye nentsimbi yentsimbi.Isinxibelelanisi sangaphambili sinikwe umngxuma ongaphakathi odityanisiweyo, kunye nowokugqibela kunye nomngxuma.I-GB/T900-1988 "I-Double stud bm = 2d".

Imisonto kwiziphelo zombini zobude obulinganayo obuphindwe kabini kufuneka ihambelane namandongomane kunye neewasha kwiindawo ezimbini eziqhagamshelweyo ezinemingxuma.GB/T901-1988 “Equal length double stud Class B”, GB/T953-1988 “Equal ubude kabini stud Class C”.Esinye isiphelo se-welding stud sidityaniswe kumphezulu wecandelo elidityanisiweyo, kwaye esinye isiphelo (isiphelo esinemisonto) sidlula kwindawo edibeneyo kunye nomngxuma wokupasa, kwaye emva koko i-washer ifakwe, kwaye i-nut ifakwe, ngoko. ukuba la macandelo mabini adityanisiweyo adityaniswe ngokupheleleyo.I-GB/T902.1 “I-Welding stud ye-welding manual”, i-GB/T902.2 “I-Welding stud ye-arc stud welding”, i-GB/T902.3 “I-Welding stud yokugcina amandla e-welding”, i-GB/T902.4 “I-Welding stud ye-Welding ixesha elifutshane ukuwelda i-ard stud”.

Ingqalelo:

Umsonto osetyenziswa kwimisonto ephindwe kabini (GB/T897-900) iqhelekile irhabaxa eqhelekileyo, kwaye umsonto ocolekileyo oqhelekileyo okanye umsonto ofanelekileyo wokutshintsha nawo unokusetyenziswa ngokwemfuno (ngokwe GB1167/T-1996 “transition fit thread. ”).Ubude obulinganayo be-double head stud -B grade, bunokusetyenziswa ngokuhambelana ne-need30Cr, 40Cr, 30CrMnSi, 35CrMoA40MnA okanye i-40B yokwenziwa kwezinto eziphathekayo, ukusebenza kwayo ngokwesivumelwano phakathi kwamaqela okubonelela kunye nemfuno. .1-2010 amalungiselelo, kodwa umxholo wayo ophezulu wekhabhoni akufanele ube mkhulu kune-0.20%, kwaye awuyi kwenziwa ngentsimbi yokusika yamahhala.

6. Ubunzima: Ukukwazi kwezinto eziphathekayo ukuchasa izinto ezinzima zendawo ezicinezelekileyo kumphezulu wayo sisalathisi sokusebenza ukulinganisa iqondo lokuthamba kunye nobunzima bezinto zetsimbi.Uvavanyo lwendlela yokuqina (iBrinell, Rockwell, Vickers)Iimfuneko zolungiselelo lwesampulu: Iziphelo ezibini zesampulu zihambelana, umphezulu usicaba, kwaye akukho oli okanye ioksidi ivunyelwe.

Indawo yovavanyo 10 ~ 35 °

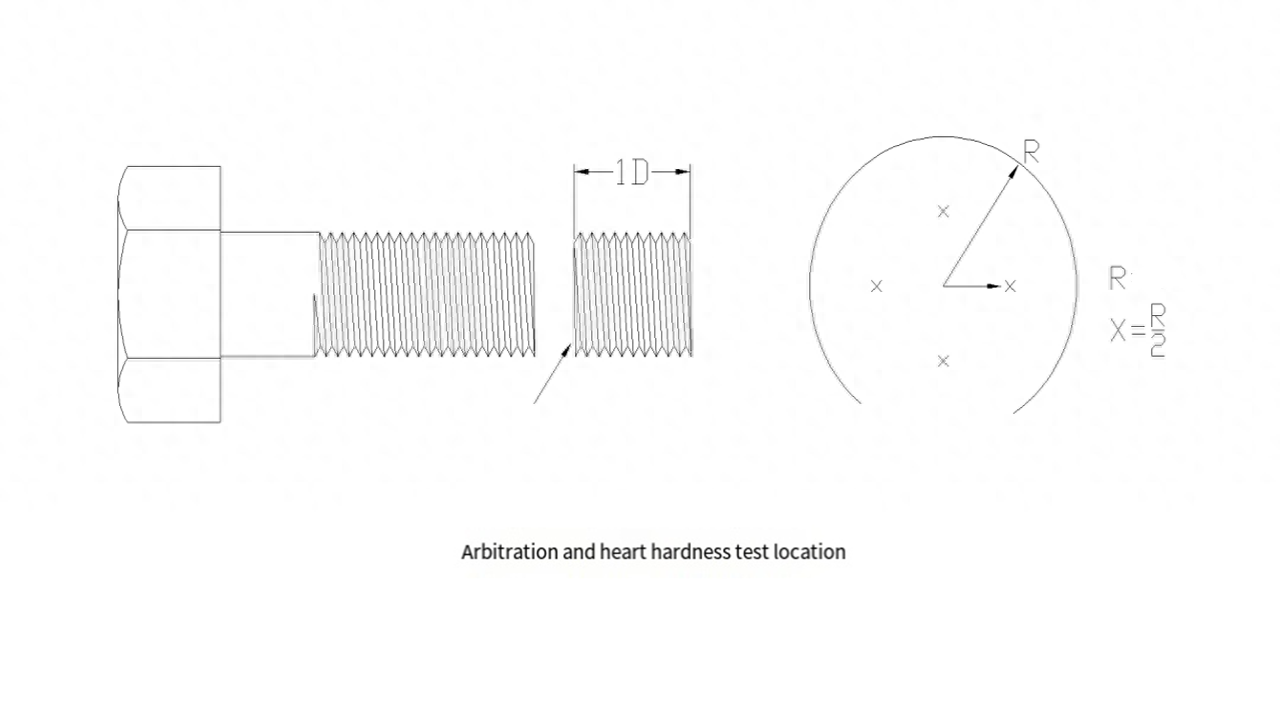

Ekubonweni kobunzima be-bolt, akukho unyango olushushu lweebholiti, kufuneka kuphela ukwenza ubunzima bomhlaba, ngaphakathi kwe-ange efanelekayo kumgca.Ukuba ibholiti yonyango lokushisa, kuyimfuneko ukusika ubulukhuni ebusweni bobubanzi ekupheleni.Indawo yokuvavanya iboniswe kumzobo.Uvavanyo lobunzima lukwi-1/2R phezu komhlaba, kwaye ubunzima budibana nomgangatho.

Ubulukhuni beBolt bunomphezulu kunye nombindi, umphezulu ubhekisa kusetyenziso lweVickers okanye ubulukhuni beRockwell emva kokususa umhlwa ongaphezulu, njl njl. 1/2 indawo yokudlala ubulukhuni, umahluko phakathi kobulukhuni obubini awukwazi ukudlula i-30HV, umphezulu uphezulu kune-30HV ebonisa ukuba umphezulu we-carburizing, awuvumelekanga, Ukuba umphezulu ungaphantsi kwe-30HV, oko kuthetha ukuba umphezulu uhlanjululwe , kwaye akuvumelekanga.

I-nut ye-8-grade jikelele kufuneka iphathwe ubushushu, kodwa akukho bushushu buphathwa, i-nut ye-8-grade nut ngokubanzi yenziwe ngentsimbi engama-35, uvavanyo lobulukhuni lucacisiwe, umgangatho oqhelekileyo awufuni, umenzi wonyango lobushushu. ivavanya ubulukhuni emva konyango lobushushu, i-metric nut yaphulwa ngokubanzi ukusuka embindini ukuvavanya ubulukhuni bentliziyo yayo, i-intshi ye-intshi yaphukile ngokubanzi kobunye bobuso (oko kukuthi, ukusika iimela ezimbini kumphezulu), ukuvavanya ubulukhuni. embindini wecandelo lomnye umphezulu, kunye namandongomane amancinci anxitywe ngokubanzi kwicandelo 0.2 ~ Vavanya ubulukhuni emva kwe-0.3mm.4.6 ~ 6.8 iibholiti azidingi unyango lobushushu;Ifakwe kwizibiyeli yodidi lwesi-2 lwamandongomane aphezulu.

Umgangatho kazwelonke we-GB3098.1 kunye nomgangatho wesizwe we-GB3098.3 umisela ukuba ukuqina kwe-arbitration kulinganiselwa kwi-1/2 yerediyo ye-cross section yecandelo.Kwimeko nayiphi na ingxabano ngexesha lokwamkelwa, ubulukhuni beVickers buya kusetyenziswa njengovavanyo lolamlo. Ubuncinci ukufundwa kwe-3 kufuneka kuthathwe kwisampulu nganye.

Indawo yovavanyo lolamlo: Xa unika ingxelo yeziphumo zovavanyo phakathi komthengi kunye nomthengisi ngeenjongo zolamlo, uvavanyo lobulukhuni buya kulinganiswa kwindawo esembindini (r/2) yeradiyasi yomphezulu osikiweyo idiamitha enye kude ukusuka ekupheleni ibholithi okanye isitudi.Ukuba ubukhulu bemveliso buvumela, thatha ukufundwa kwe-4 ekupheleni kwale bholithi okanye i-stud.Iimveliso zedayamitha ezincinci zinokuvavanywa kusetyenziswa indawo ehambelanayo yetheminali yentloko yebholithi ehambelana nomphezulu osikiweyo ongentla.Uvavanyo lwesiqhelo, ubulukhuni beebholiti, izikrufu okanye izikhonkwane zinokuvavanywa entloko, emsileni okanye eshank emva kokususwa ngokufanelekileyo komphezulu.

Kuzo zonke izigaba, ukuba ixabiso lovavanyo ligqithise umda ophezulu wobunzima, umboniso kufuneka ususwe kwindawo yedayamitha yegama ukusuka ekupheleni komfanekiso, kunye nombindi wesampulu kunye nomzila wentambo kwindawo ephakathi. uvavanyo, ixabiso retest akufuneki lidlule umda ophezulu ubulukhuni, ukuba ngamathandabuzo, ubulukhuni Vickers (HV) kufuneka yamkelwe njengesigqibo.Uvavanyo lobulukhuni bomphezulu lunokufumaneka ekupheleni kwemveliso okanye kumda wehexagon, kwaye indawo yovavanyo kufuneka ibe phantsi kancinane okanye ipolishwe ukuqinisekisa ukuphindwa kovavanyo kunye nemeko eyinyani yomfanekiso womphezulu.I-HV0.3 isetyenziswa kuvavanyo lolamlo lovavanyo lobulukhuni bomphezulu.Ubunzima bomphezulu obuvavanywe nge-HV0.3 buya kuthelekiswa nexabiso le-core hardness test value nayo ihlolwe nge-HVo.3, kwaye umahluko awuyi kudlula amaxabiso obunzima be-HV angama-30.Ubulukhuni bobuso obukhulu kunobunzima obungundoqo 30 HV ubulukhuni amaxabiso abonisa ukuba isampuli iye carburized.Kwiimveliso ezinamabanga e-8.8 ukuya kwi-12.9, umahluko phakathi kokuqina komphezulu kunye nobunzima obungundoqo ungasetyenziselwa ukufumanisa ukuba imveliso ine-carburizing phezu komhlaba.Ubunzima bemveliso abuhambelani ngokuthe ngqo kumandla obunzima bethiyori.Ukumiselwa kwexabiso lobunzima obukhulu akusekelwe ekuqwalaselweni komda wamandla aphezulu.

Qaphela: Kufuneka kuqatshelwe ukuba ukuguquguquka kwexabiso lobulukhuni kubangelwa kunyango lokutshisa i-carburizing okanye ukusebenza okubandayo.

Ixesha lokuposa: Sep-23-2023